<

►

>

TECHNICAL DESCRIPTION

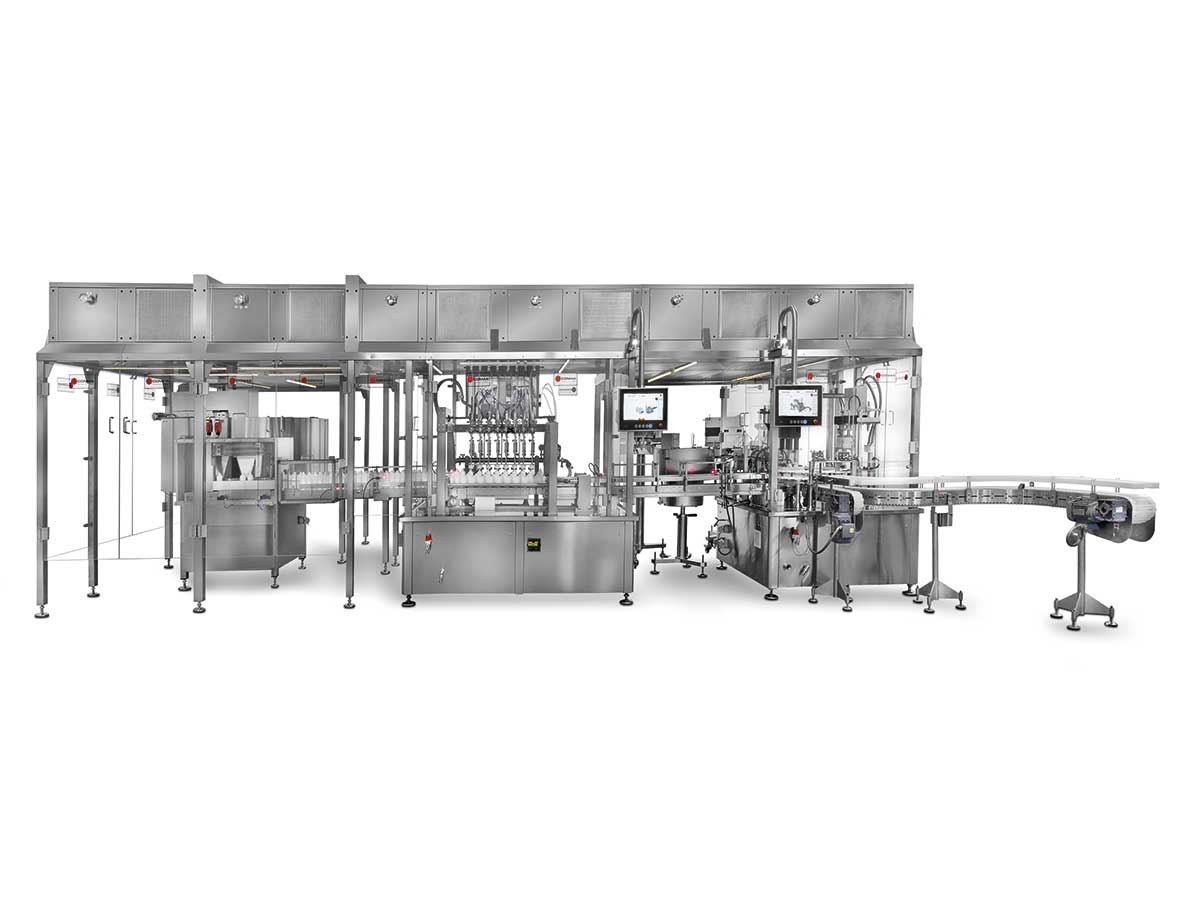

- Loading / Unloading conveyor for bottles.

- Electronic controls to verify the presence of the bottles Double endless screw takes group of 4/6 bottles carrying under the filling area.

- Checking unit to control presence of bottle in the endless screw.

- If the bottle is missed the machine stops automatically.

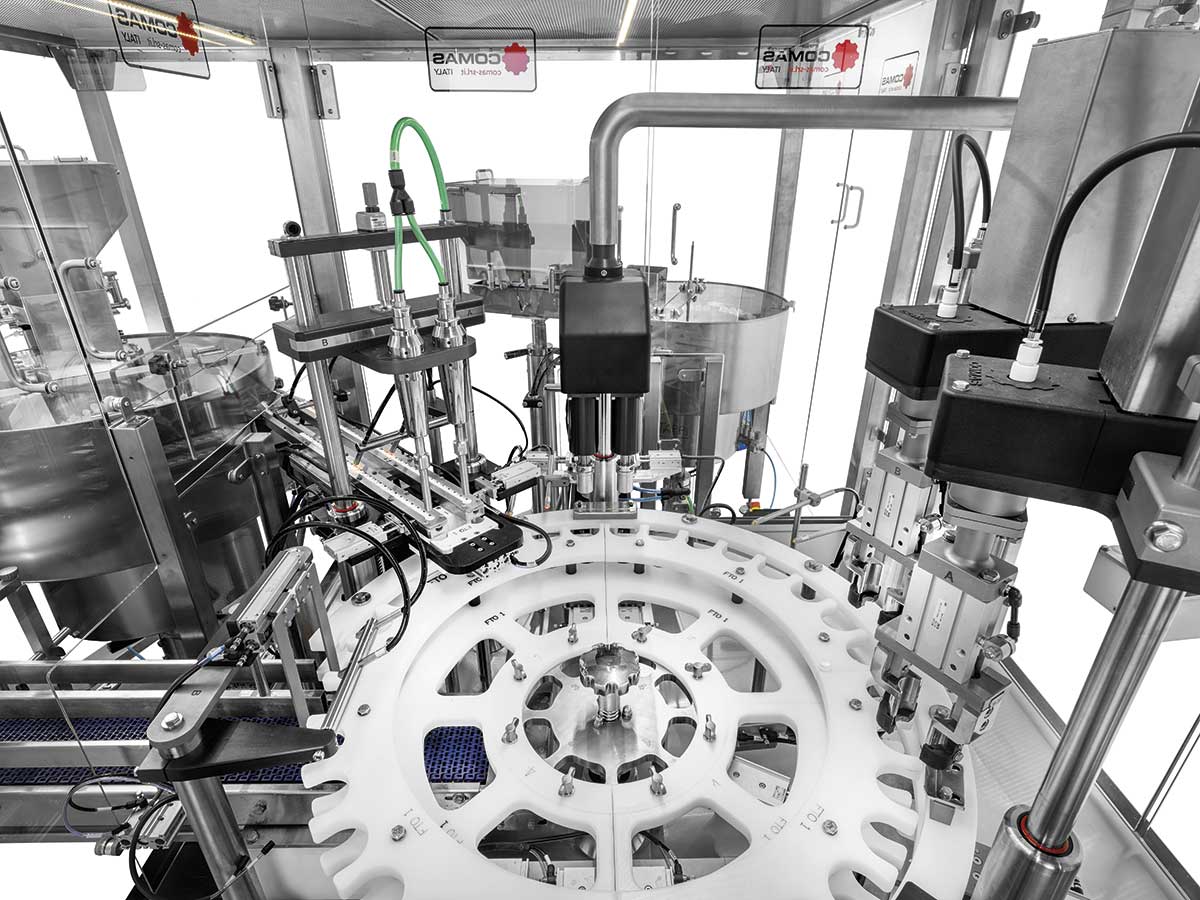

- Filling group consisting of 4/6 solid dispensers (according to the model) assembled on fitting clamps.

- Lobe supplier pump for liquids / creams with 3 inverter programmable speeds with variable acceleration and deceleration.

- A time management control panel for needle opening and their movement.

- Needle movement group with a BRUSHLESS ENGINE with a 250MM RUN, with 4 programmable speeds (1 descent speed and 3 independent ascending speeds)

- Nr. 4/6 needles with pneumatic closure with clamp fittings (according to the models)

- Adjustable valve aperture at the end of each bottle During the filling operation, the second endless screw loads other 4/6 bottles.

- When the first filling operation is finished the mass feeder section moves to the other 4/6 bottles ready to be filled.

- Touch Screen control panel with tube support, complete with all necessary switches, warning lights, start-, stop- and emergency push buttons