<

►

>

TECHNICAL DESCRIPTION

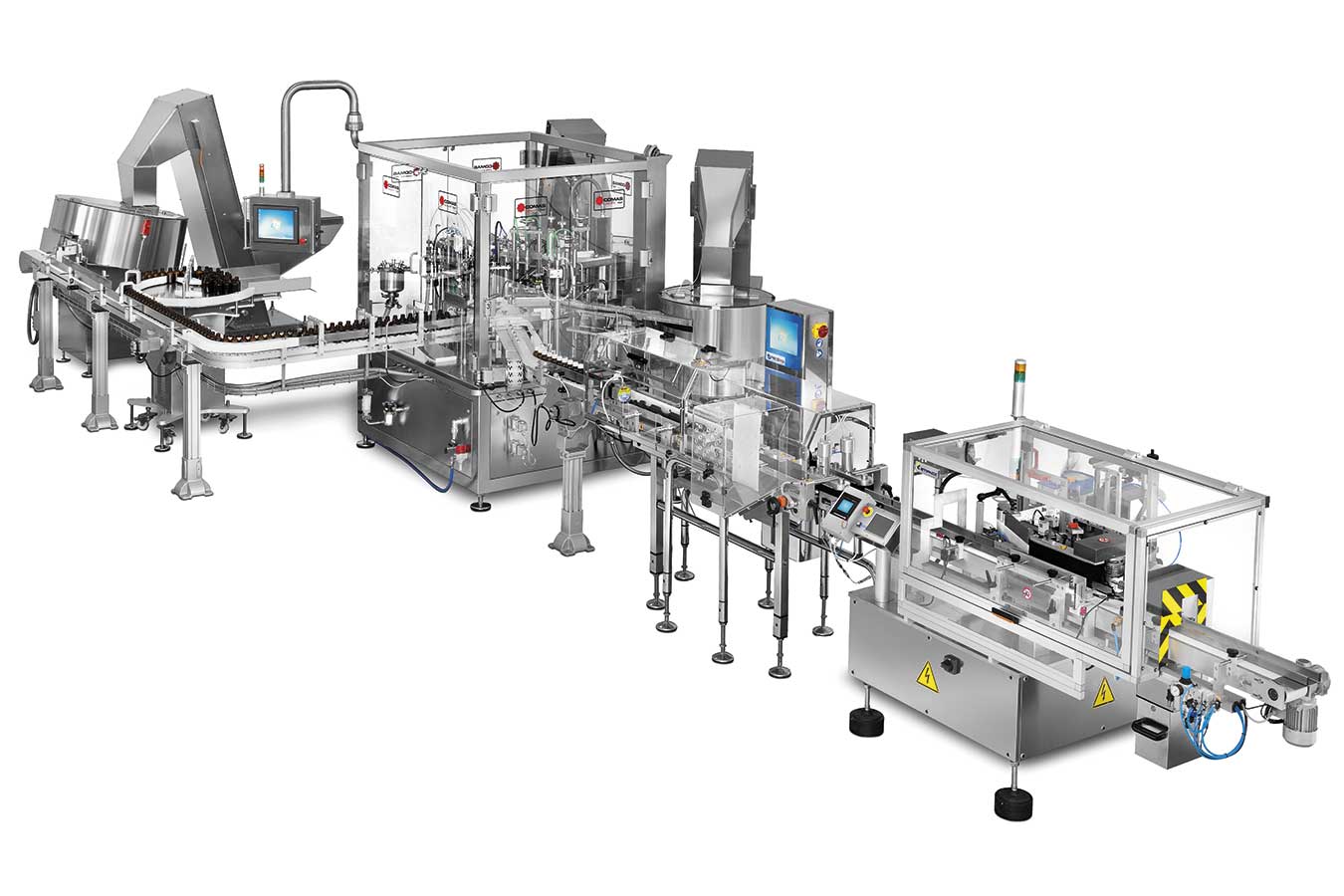

- Infeed conveyor.

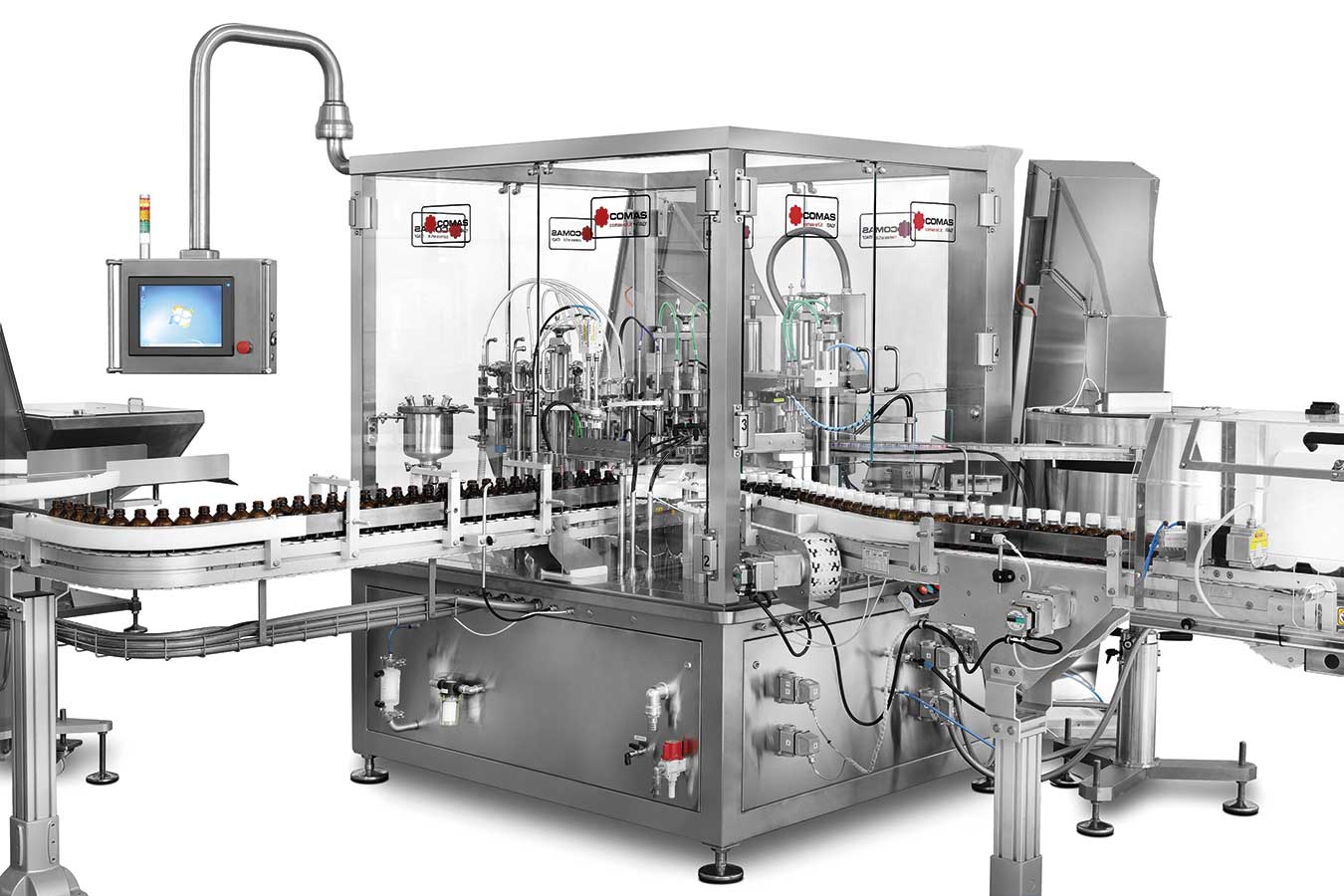

- Glass and anodized aluminium accident protections.

- A stainless steel standard AISI 304 frame.

- Motorizing system for the movements of various groups.

- 16 positions star-wheel with intermittent movement. The Alternative movement of the star is made by an intermittent mechanical transmission. Bottle presence control in the star. If the presence of the bottle shouldn’t be noticed the machine stops automatically.

- Set of 4/6 volumetric syringes. The syringes are completely demountable for cleaning and the regulation of their dosage is extremely simple. Each syringe is complete of an aspiration valve and product discharge.

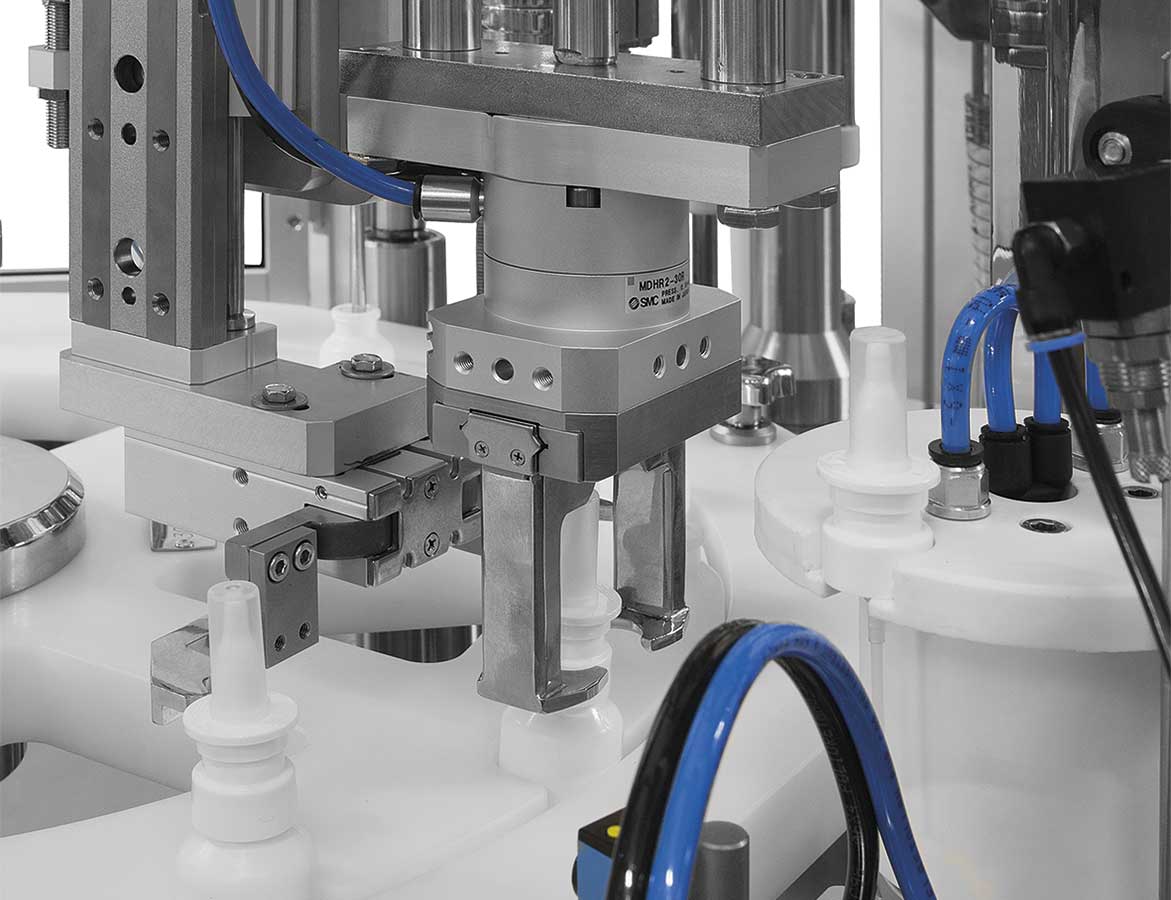

- Needle holder group of 4/6 needles that enter into the bottles during the filling operations.

- Automatic loading supply equipped with a stainless steel AISI 304/316 sliding device for the selection, transport and positioning on the bottle of under-caps/caps or cover-caps.

- Presence control of under-caps/caps/cover-caps on the bottle. If the control has a negative outcome, the machine stops. Alternatively the machine can reject the defective object. Adjustable magnetic clutch head closure for screw caps. Alternatively it is possible to mount a head seamer or a head for pressure closure caps. PLC, steel electric panel, machine control panel eventual touch screen. Outfeed conveyor.