<

►

>

TECHNICAL DESCRIPTION

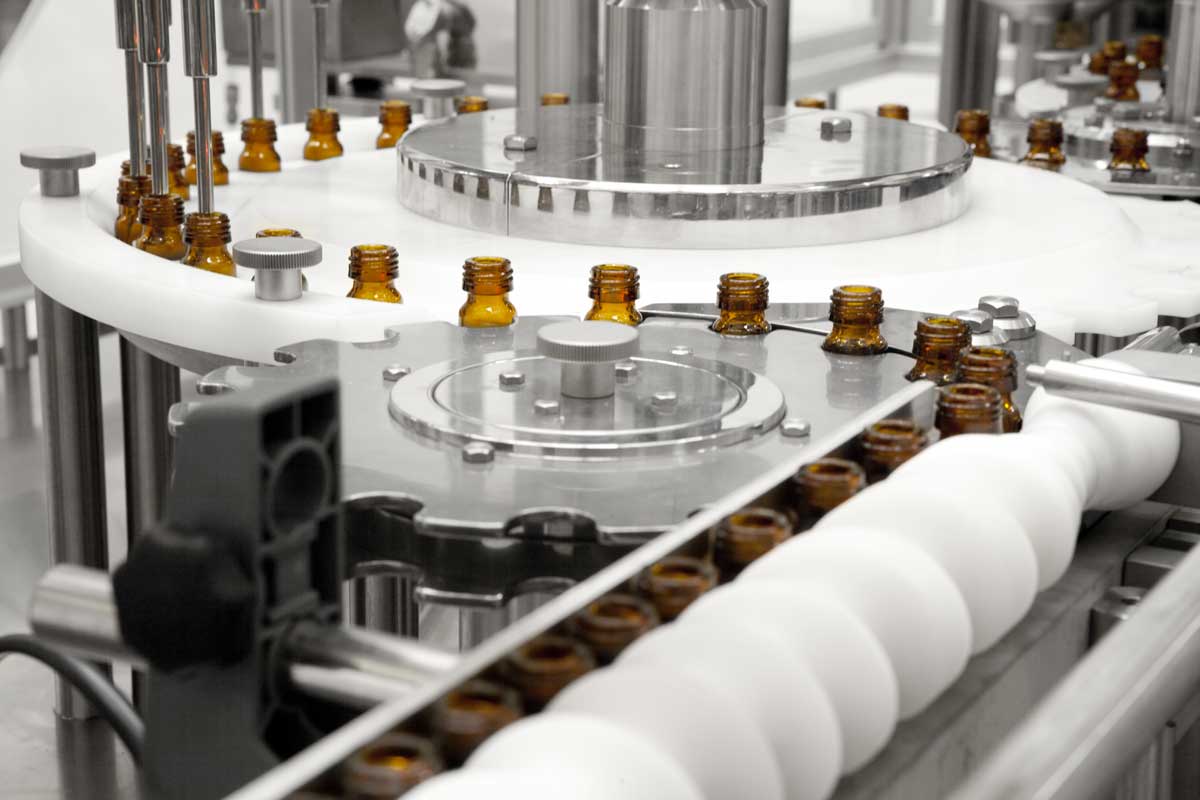

- Mechanical feeder with elevator.

- Infeed conveyor.

- Glass and anodized aluminium accident protections.A stainless steel standard AISI 304 frame.

- Motorizing system for the movements of various groups.

- The speed of the machine is adjustable electronically with an inverter.

- Set of stainless steel stars with continuous movement to carry the bottles to the various filling and capping phases.

- Set of endless screws to outdistance the bottles at the entry and the exit of the star.

- Bottle presence control in the star: If the bottle is not present the machine stops, alternatively, a no bottle-no filling-no capping system can be used, so that the machine does not work on an empty station.

- Filling with 8/10/12 syringes with stainless steel AISI 316L cylinder. The syringes are completely demountable for cleaning. Each syringe is complete of an aspiration valve and product discharge

- The dosage is adjustable electronically.

- Set of 8 needles with adjustable heights that enter into the bottles and follow them during the filling phases.

- Automatic supply with elevator, equipped with a stainless steel AISI 316 sliding device and star transfer for the selection, transport and positioning on the bottle of eventual under-caps/caps or cover-caps.

- Presence control of under-caps/caps/cover-caps on the bottle. If the control has a negative outcome, the machine can reject the defective object.

- Set of closure heads that carry out the application and the pressure closure of the cap on the bottle. Alternatively it is possible to mount a head seamer or a head for screw caps.

- PLC, steel electric panel, machine control panel eventual touch screen.

- Outfeed conveyor.