<

►

>

TECHNICAL DESCRIPTION

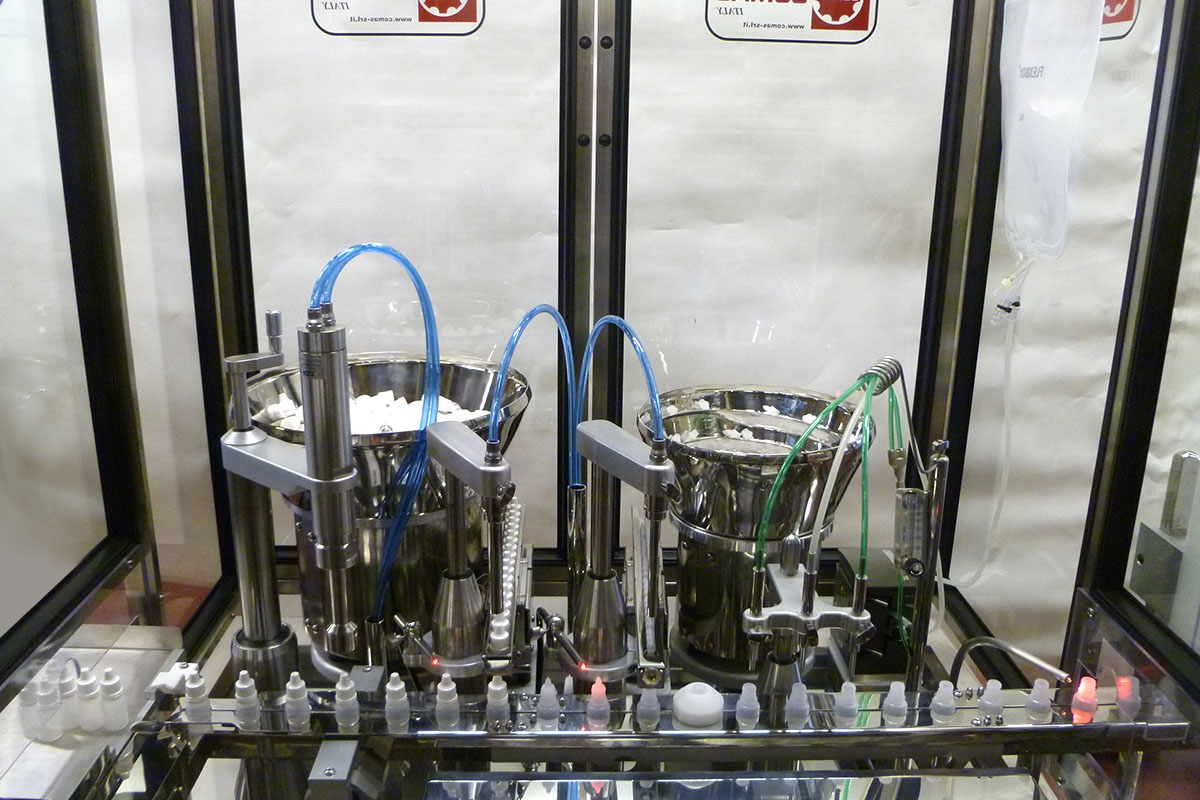

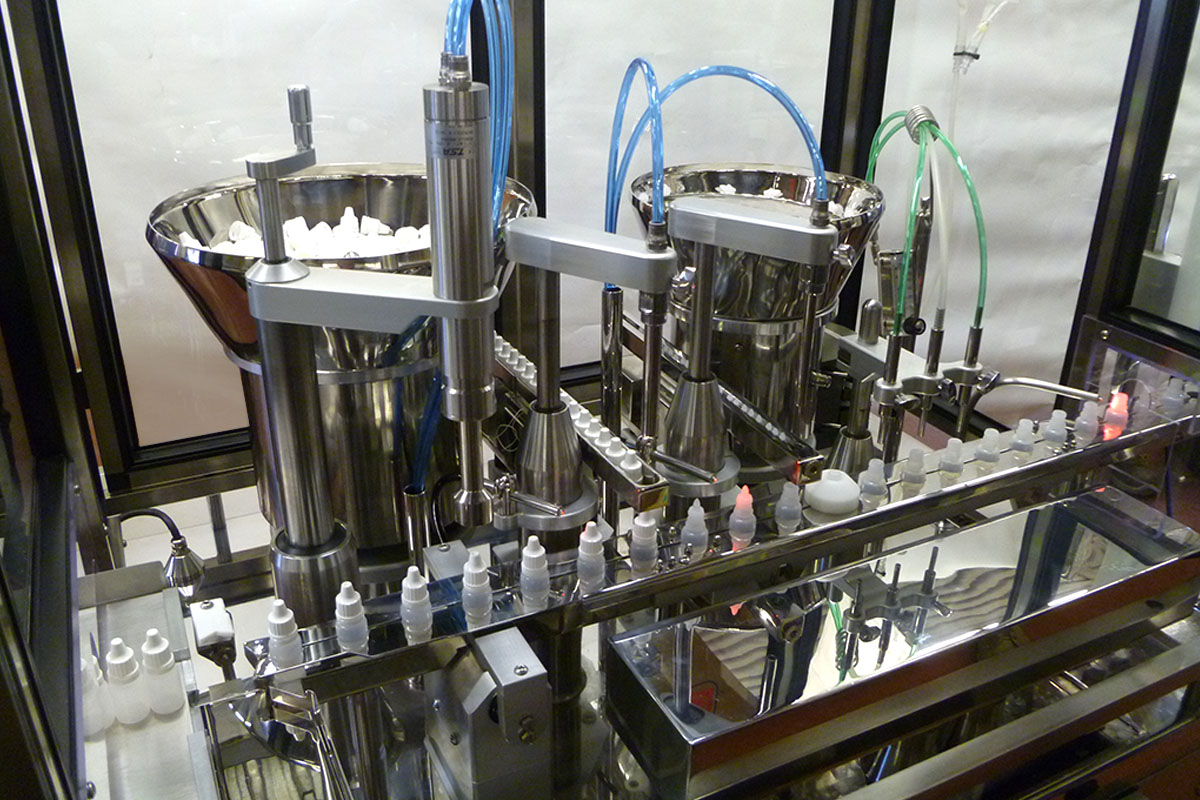

- Safety enclosure around upper machine part, with hinged protection covers built in glass panels with stainless steel frames and provided with safety micro-switches stopping the machine when covering doors are opened.

- Stronger frame to support HEPA filters.

- Rotary table in Stainless Steel AISI 316 to feed the containers to the filling area

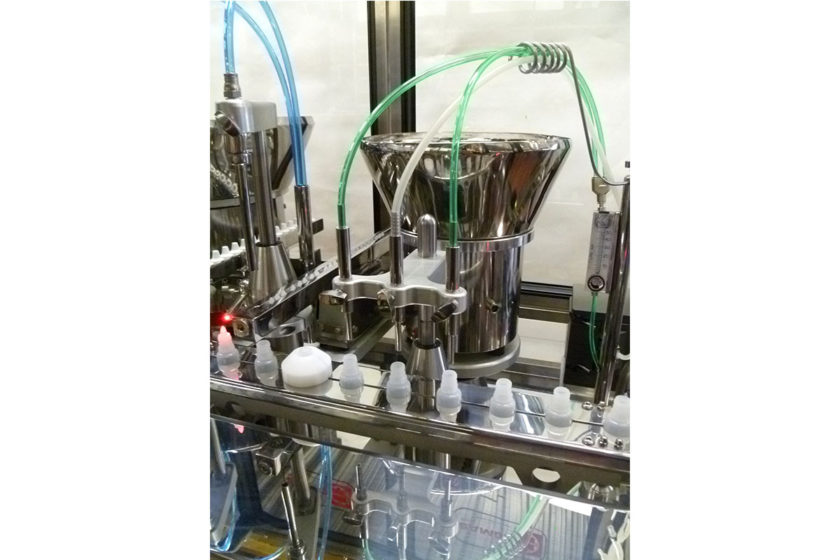

- Advancement of the bottles due to a double “walking beam” to hold the container during the filling – stoppering – and closing steps.

- Checking unit to test the presence of the container. If no bottle is detected the machine will not dose. After 3 consecutive machines will stop automatically.Filling unit composed by one peristaltic pump, volumetric syringe, time/pressure unit or powder dosing head.

- One nozzle in AISI 316 to dose. For the nitrogen, a double pipe nozzle will be supplied to blow during (before/after) the filling.

- Automatic loading supply equipped with a stainless steel AISI 316 sliding device for the selection, transport and positioning on the bottle of undercap and/or cap.

- Presence control of under-cap and/or cap on the bottle. If the control has a negative outcome, the machine stops. Alternatively the machine can reject the defective object.

- Automatic closing head.

- Basket tray for outfeed containers.

- PLC, steel electric panel, machine control panel eventual touch screen.

- The internal parts are placed to allow a perfect flow of laminar flow through the working area.

- Finishes and components easily sterilizable.

- Mechanical out-put : Up to 25 pcs/min.