<

►

>

TECHNICAL DESCRIPTION

- Manual bottle loading on the conveyor or into pucks of the RMC4. A chain provided of indexing motion handles bottles and pucks. The chain transfers bottles/pucks to the filling and capping stations.

- Glass and anodized aluminium accident protections.

- A stainless steel standard AISI 304 frame.

- Motorizing system and various group movements. Mechanical speed motor variator.

- Electronic controls to verify the presence of the bottle, the cap, and the eventual under-cap.

- Pneumatic gates positioned in proximity of the work areas to allow accesses and outputs of pucks/bottles under the working areas.

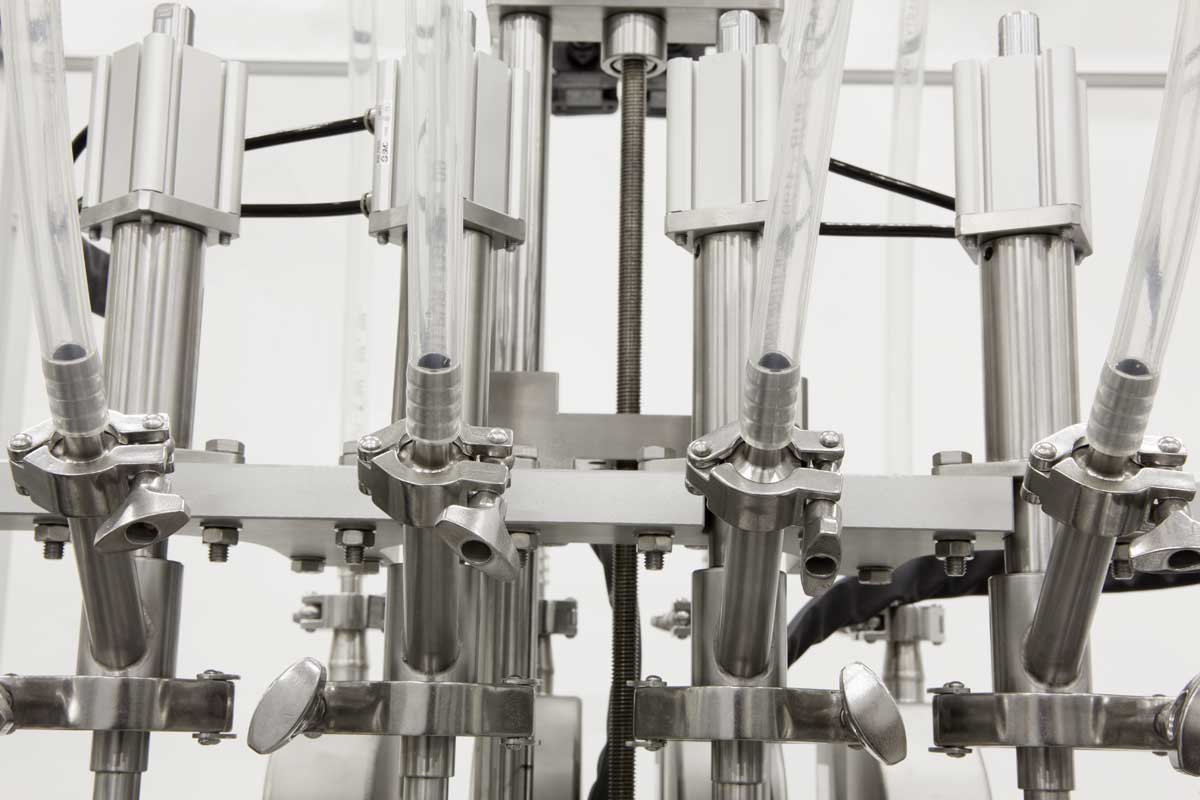

- Filling group consisting of 4/6 solid dispensers (according to the model) assembled on fitting clamps.

- Lobe supplier pump for liquids / creams with 3 inverter programmable speeds with variable acceleration and deceleration.

- A time management control panel for needle opening and their movement.

- Needle holder group of 4/6 needles that enter into the bottles during the filling operations.Needle movement group with a BRUSHLESS ENGINE with a 250MM RUN, with 4 programmable speeds (1 descent speed and 3 independent ascending speeds).

- Nr. 4/6 needles with pneumatic closure with clamp fittings (according to the models).

- Adjustable valve aperture at the end of each bottle.

- Conveyor transfer the bottles/pucks to the star-wheel capping area.

- Manual cap loading by an operator.

- Possibility of inserting an automatic supplier.

- Closure head with adjustable magnetic clutch for screw-caps. Alternatively it is possible to assemble a head seamer or a head for the pressure closure of the caps.

- PLC, steel electric panel,machinery with a touch screen control panel, possibility of memorizing up to 50 dosage programs.

- Bottle unload with a double system of pick and place for bottle extraction from the puck to the unloading conveyor.