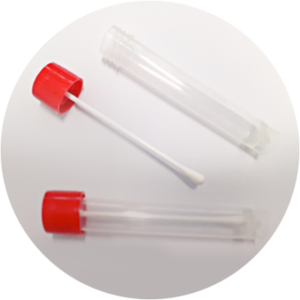

For test tube Ø16 Screw-on cap

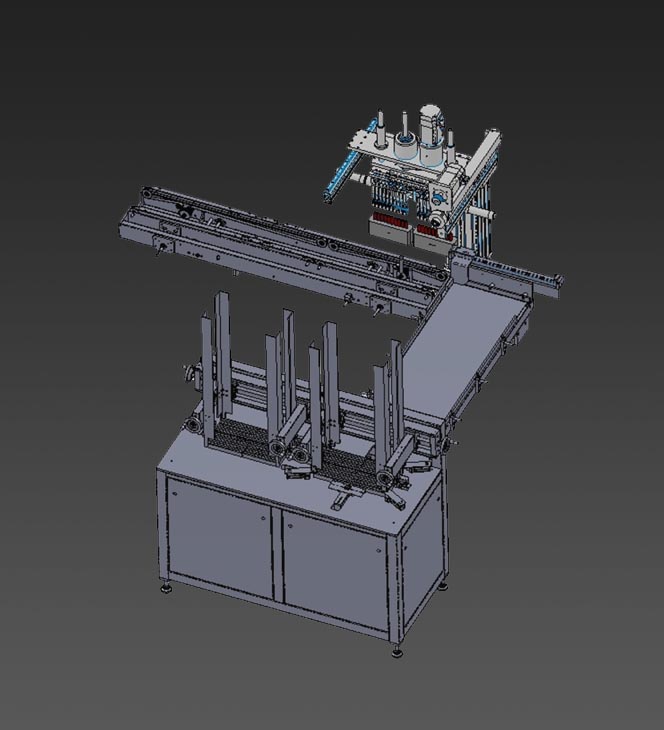

Complete line for test tubes to be used for testing virus (ex. COVID 19)

Complete line for test tubes to be used for testing virus (ex. COVID 19)

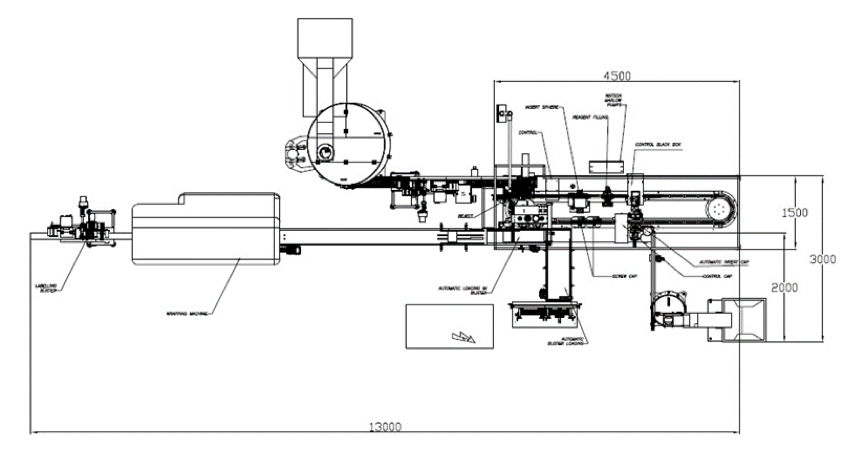

Machine working flow and overall dimensions

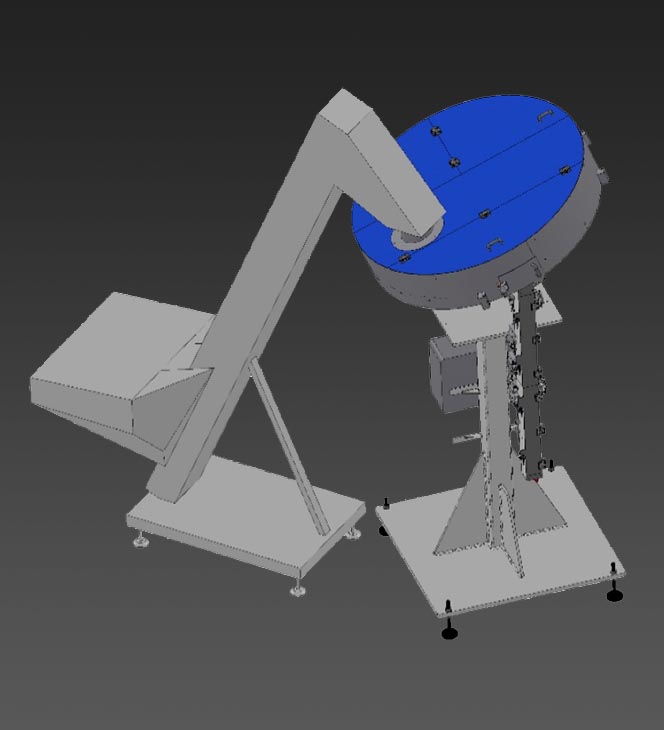

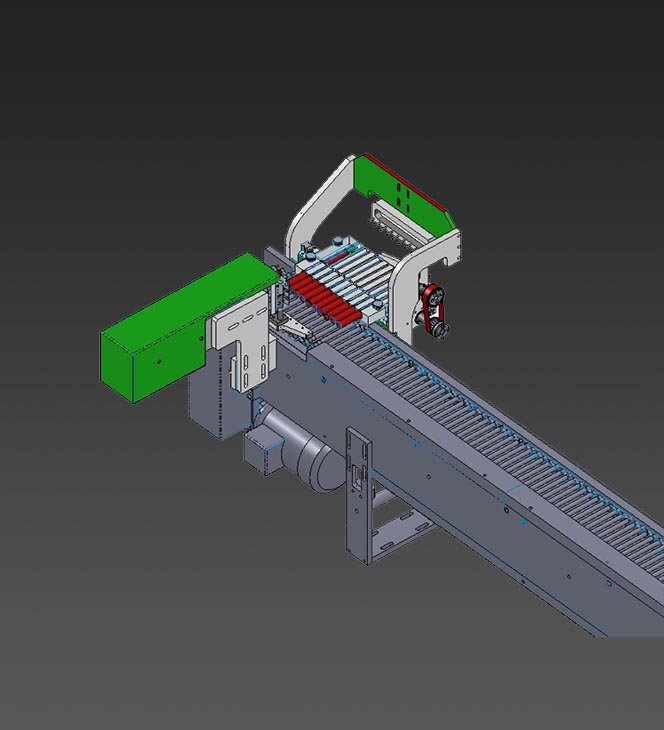

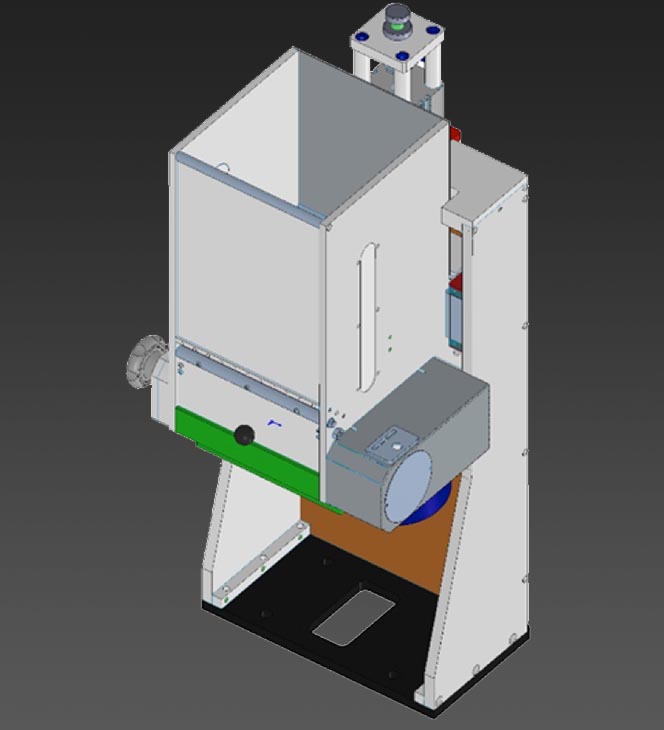

The operator feeds the box container with tubes to the AUTOMATIC ELEVATOR WITH CENTRIFUGAL UNSCRAMBLER. Automatically the test tubes are loaded lay down and bring to the 1st station of the Machine by a roller conveyor

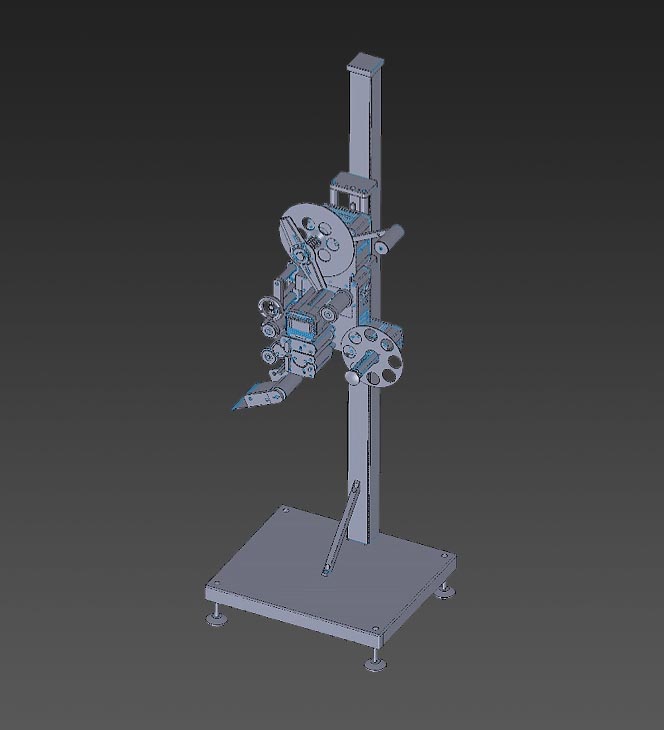

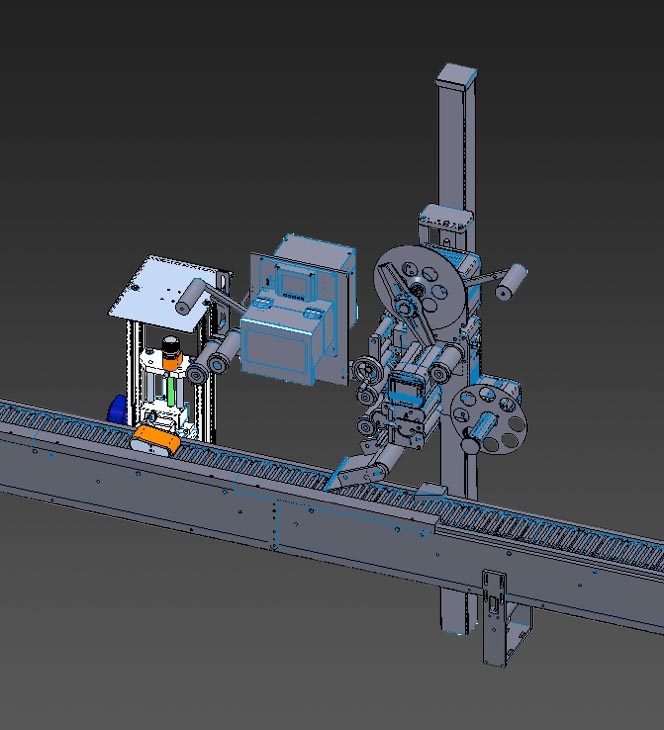

Automatic labelling machine model 100 for distribution of self-adhesive labels on test tubes with printer system for batch number and expiry date.

The machine is already composed with a Group thermal printer for printing the expiry date and the batch number

Roller conveyor belt to carry forward the test tubes

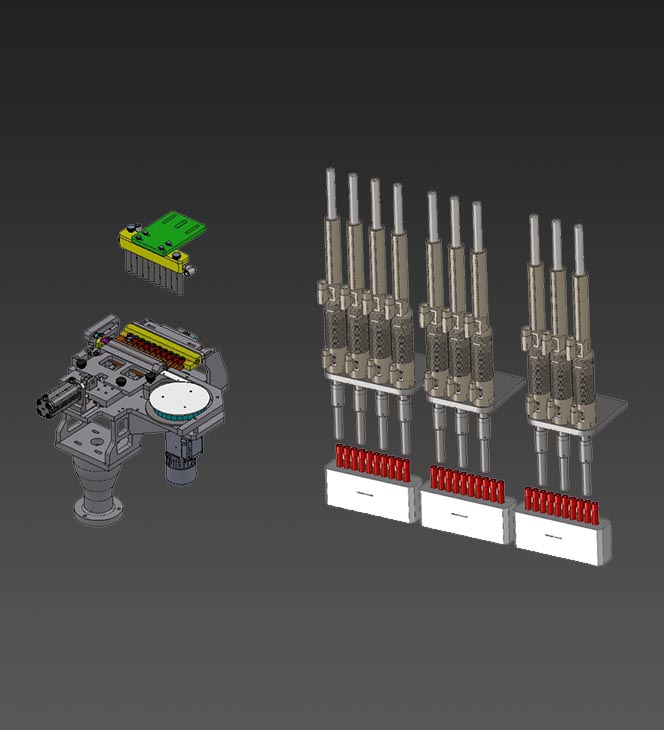

Automatic loading station by a pick & place system that load into the pucks 10 test tubes each time by a revolver system.

Liquid filling station composed by 10 peristaltic pumps.

The filling dose is easily adjustable by touch screen

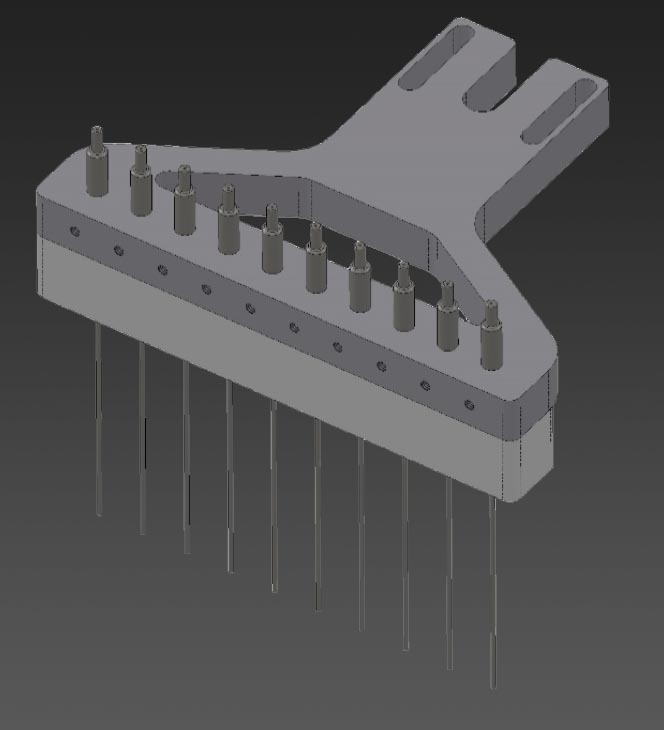

Set of 10 nozzles made of AISI 316 for liquid

Granules station for the agitator are placed inside the test tubes.

One transfer chute in AISI 316 for cap to load 10 caps each step.

Three capping stations for closing test tubes with screw-on cap system.

Test tubes are automatically removed from the pucks and placed on the Blister of 50/100 pieces. (TBD). Including conveyor + magazine of 1mt. capacity, every 30 minutes.

Completed blister move out on the outfeed conveyor and are packed automatically

Automatic labelling machine model 100 for distribution of self-adhesive labels on Blisters wrapped with printer system for batch number and expiry date.

The machine is already composed with a group thermal printer for printing the expiry date and the batch number